Sensor technology service provider

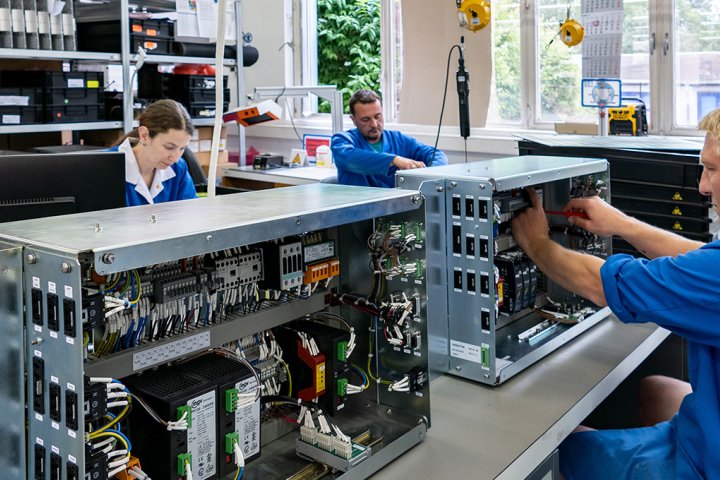

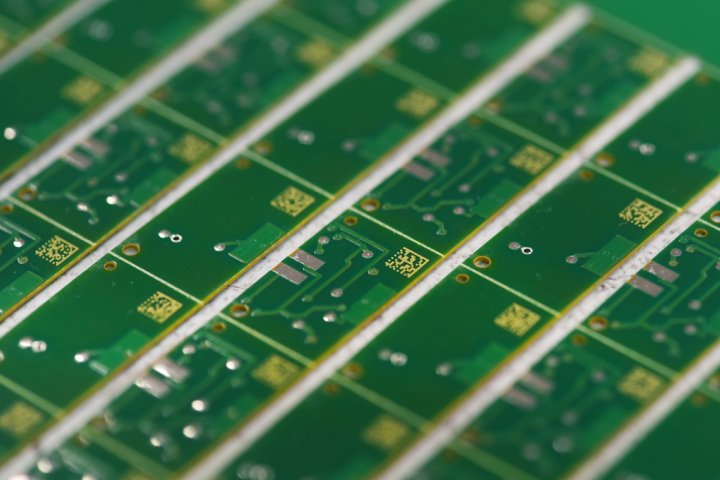

Industry 4.0 - the reliability of machines and systems is the basic prerequisite for production, assembly, testing, and maintenance processes. As an experienced sensor technology service provider, we apply our expertise in hardware and software to ensure that modern sensor technology is part of our broad portfolio of electronic components and devices.

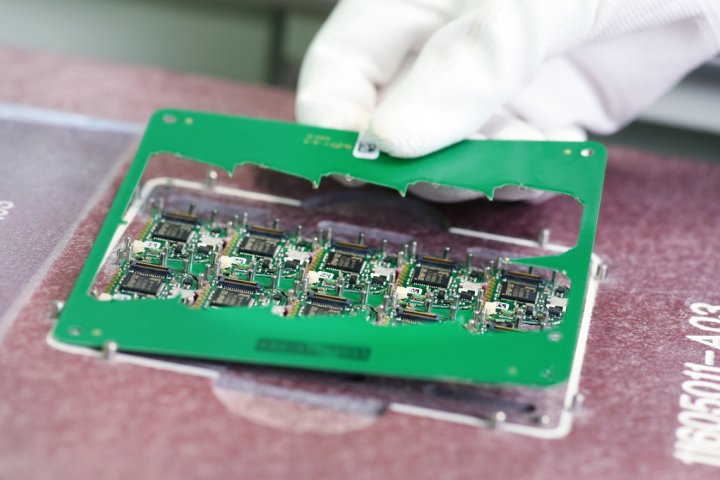

We develop and manufacture sensor technology for OEMs and users that is precisely tailored to industry applications. Thanks to our high in-house development and production depth, customer-specific sensor solutions can be implemented efficiently by a trusted sensor technology service provider.

Intelligent networking

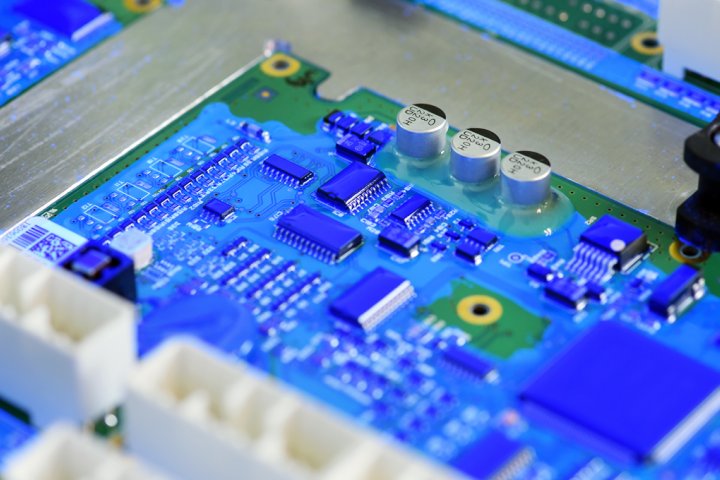

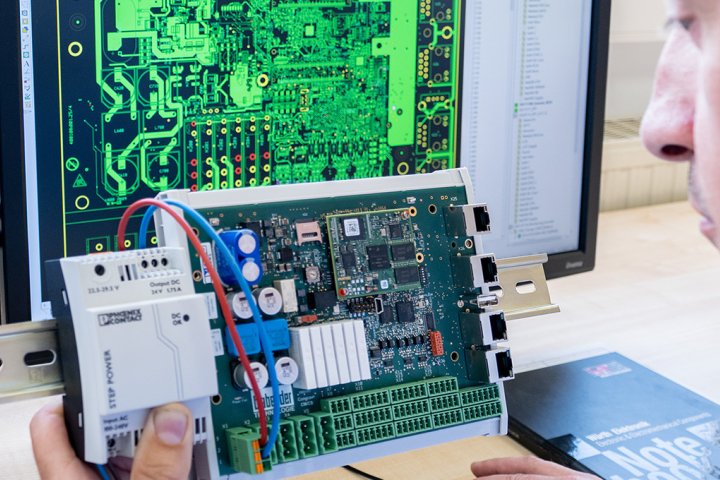

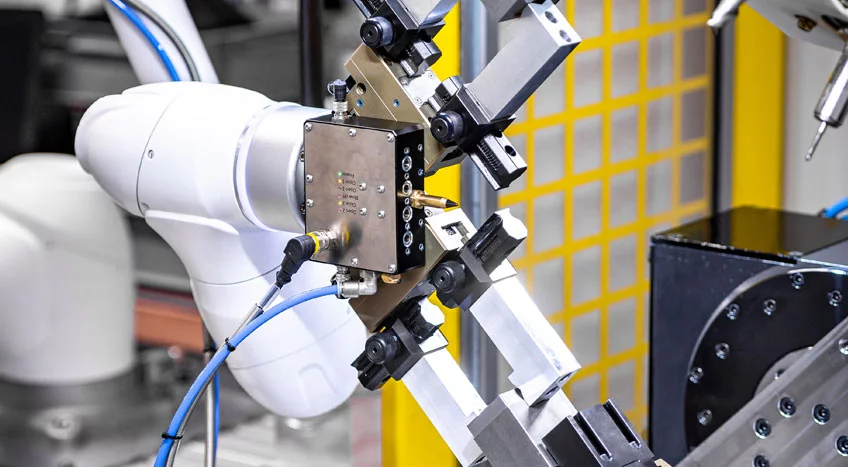

The extensive networking in smart factory and plant automation in the sense of Industry 4.0 as well as in agriculture requires the immediate availability of all relevant operational information. The intelligent networking of development, production and logistics is a central challenge for us as a DMS system service provider. Thanks to a wide range of industrial interfaces and evaluation algorithms, smart sensors from EPSa ensure the optimal integration and networking of machines and processes.

Decentralised sensor use

For example, the self-diagnosis of machines and plants through decentralised sensor technology has the advantage that communication lines to the central control are relieved. Information is only provided when a fault or anomaly is detected. Modern sensors and local edge devices can decide for themselves when such an anomaly is present. Together with limit and pressure switches, our sensor solutions offer you a reliable and simple complete solution for monitoring remote applications via cloud. This enables you to meet customer requirements for IoT and Industry 4.0 with the support of a capable sensor technology service provider.

Advantages

- Increased machine and plant availability through condition monitoring

- Simple use of status information through efficient data reduction

- Conservation of PLC and communication resources

- Visualisation through digital signage

Applications

- Automation

- Production and test bench monitoring

- Flow and level measurement

- Analysis of liquids and solids

- 2D/3D measurement technology

- Position detection: position and inclination

- Attendance recording

- Sorting, geometry, and colour recognition

- Calibration of tools and test equipment